![]()

OIKOS MATERIALS is able to supply the best and the most advanced and modern fibres of the market and helps you in choosing the product to use, according to the final utilization. We are able to select for you the best high modulus and high tenacity fibres available. Carbon fibres, glass fibres, aramidic and similar fibres, polyester fibres and polyamide fibres. High performance and special fibres.

![]()

OIKONFIBRE consists of rigid-rod chain molecules of PBO. OIKONFIBRE is the next generation super-fibre with strength and modulus almost doubles that of p-Aramid fibre. It shows 100° C higher decomposition temperature than p-Aramid fibre. The limiting oxygen index is 68 which is the highest among organic super fibre. There are two types of fibres: AS (as spun) and HM (high modulus). HM is different from AS in modulus, moisture regain, etc.

![]()

The carbon fibres are a very light fibre (density 1,78 g/cm3), very resistant (Tenacity 4800 MPa, modulus of elasticity 240 GPa) and flexible, easy to process. We also supply two types of oxidized technical fibres: the first can be used in many different application like: aircraft brakes, fire barriers, thermal insulation, technical textiles. The second are suitable for the following applications: aerospace, automotive, protective, apparel furniture, bedding.

![]()

We are able to supply very special fibreglass named OIKONGLASS is a high-strength glass fibre, an excellent competitor for carbon or aramid in certain applications. Because this is a magnesium-alumina-silicate glass, it has excellent mechanical properties for uses in such varied and demanding applications as helicopter blades, rescue worker air tanks, airplane flooring, ballistic armor, windsurfers, running shoes and high-temperature filtration bags

![]()

OIKONTREX is a special fibre, whose architecture resembles a hybrid of filament winding and weaving. Like filament winding, OIKONTREX fibre features seamless fibres continuity from end to end of a part. Like woven materials, OIKONTREX fibre are mechanically interlocked with one another. The combination, however, is quite extraordinary. When functioning as a composite reinforcement, OIKONTREX exhibits remarkable properties because it is highly efficient in distributing loads.

![]()

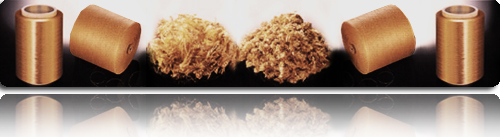

POLYPOWER is a subset of the thermoplastic polyethylene. It has extremely long chains, with molecular weight numbering in the millions, usually between 2 and 6 million. The longer chain serves to transfer load more effectively to the polymer backbone by strengthening intermolecular interactions.

This results in a very tough material, with the highest impact strength of any thermoplastic presently made. It is highly resistant to corrosive chemicals, with exception of oxidizing acids. It has extremely low humidity absorption, has a very low coefficient of friction, is self-lubricating, and is highly resistant to abrasion (15 times more resistant to abrasion than carbon steel). Its coefficient of friction is significantly lower than that of nylon and acetal, and is comparable to that of Teflon, but it has better abrasion resistance than Teflon. It is odorless, tasteless, and nontoxic. It is suitable for production of cables for traction. It is especially used for sports such as kite surfing, paragliding, mountaineering, fishing, and for bullet proof jackets production.

The cords in POLYPOWER have an exceptional strength, comparable to that of steel cables, but with the advantage of very good resistance to be twisted and bent. Unlike the first generation of wires in high density polyethylene, today POLYPOWER has overcome the disadvantage caused by high elasticity that made it dimensionally not too stable.

POLYPOWER fibre produced today has special features as for diameter resistance, we talk about a few kilo per wire with diameters of about 0,10-0,12 mm, and in particular shows a thread that is practically free of elasticity.